VANE RAIL

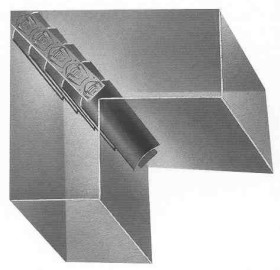

Air travelling throughout a duct is slowed up when it reaches a right turn angle. This “slow-up” is detrimental to the efficiency of the duct system, therefore air turning vane assemblies are used to guide air evenly around such turns. With today’s high labor costs, it is expensive for shops to produce their own air turning assemblies. That is why Duro Dyne Vane Rail is a major contribution to sheet metal shops that require efficient, yet inexpensive air turning assemblies. With Duro Vane Rail, which is a pre-fab side rail, layout time is eliminated. Vanes can be sheared from scrap metal without tab cutting, and quickly assembled to rails with only one blow of a ball peen hammer. Duro Dyne Vane Rail, made up of 24 gauge galvanized steel, is precision-stamped and slotted assuring uniform spacing of vanes, and the fastest, easiest, most economical construction of vane assemblies. Duro Dyne Vane Rail is specially embossed adding strength and sturdiness to the finished section. Vane Rail can be used to make quality turning vanes for any size elbow including change of size elbows.

| Item Number | Code | Description | Quantity |

| 4002 | VR2 | Galvanized Steel Vane Rail | 100 ft. Continuous Coil |

| 4003 | JVR2 | Galvanized Steel Vane Rail Junior Vane Rail | Two 100 ft. Continuous Coil |

| 4007 | VR2SS | 300 Series Stainless Steel Vane Rail | 100 ft. Continuous Coil |

| 4008 | VR2AL | Aluminum Vane Rail | 100 ft. Continuous Coil |

Fabricating Air Turning Vanes

- Shear and form the vanes as indicated. Position the vanes in the Vane Rail slot.

The slots force the vanes to take the correct curve.

- Secure the protruding vane with a ball peen hammer.

- An extra deep depression in Vane Rail allows for superior gripping action.

The vane assembly is then fastened in the elbow.