FABRICATING A FLEXIBLE CONNECTION

How to Stiffen Flexible Connector

When installing large size flexible connectors in a duct system, some type of stiffening agent is usually required to keep the unit relatively rigid. Some contractors use angle iron, while in many cases a bar slip connection is used to achieve this result. Now it is possible to save valuable time and material by forming Duro Dyne’s Grip Loc Seam found on Metal Fab and Super Metal Fab, to rigidize the connector over long sections. This simple method of stiffening the sides of Duro Dyne Flexible Connector can eliminate the costly addition of angle iron used to perform this job.

Here is how it is done:

| 1) Lay out Connector as you normally do. |  |

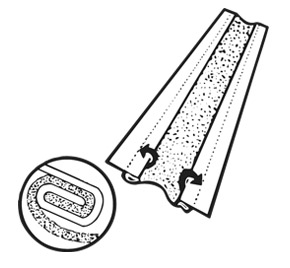

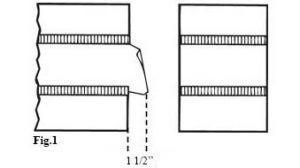

| 2) Bend the Grip Loc seam up to 90º on a brake as indicated in the drawing. |

|

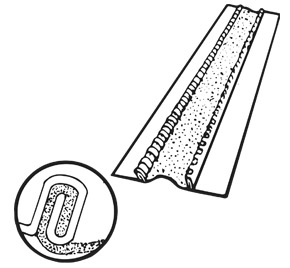

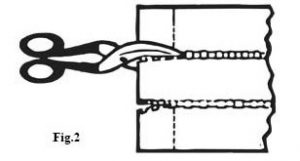

| 3) Using a heavy snips, notch the seam at the bend points. |

|

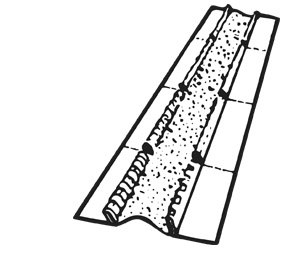

| 4) Bend to form completed connector. |  |

How to Seam Flexible Connector

Here is how we suggest the ends of Duro Dyne Connector be prepared for making a joint.

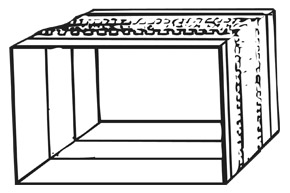

| 1) Cut through center of lock as indicated. Cut 1″ to 1-1/2″ deep to allow sufficient lap. |

|

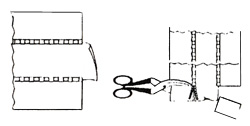

| 2) From the edge of the connector, cut away metal as indicated. The metal falls away exposing the fabric ready for seaming. |

|

| 3) After bending the connector to size, overlapped metal may be riveted, screwed or spot welded. The fabric joint is easily and quickly closed using a Duro stapler. |  |